- Solar Power Plant Project Report

- Detailed Project Report Solar Power Plant Pdf Download Full

- Solar System Projects Pdf

Aspects of solar power project development, particularly for smaller developers, will help ensure that new PV projects are well-designed, well-executed, and built to last. Enhancing access to power is a key priority for the International Finance Corporation (IFC), and solar power is an area where we have significant expertise. Make solar modules which generate electrical power from sunlight, as distinguished from a 'solar thermal module' or 'solar hot water panel.' The electrical energy generated from solar modules, colloquially referred to as solar power, is an example of solar energy.

GREENERGY POWER (I) PVT Ltd

Submitted to: Prof. D. Shreenivasachary

Submitted by: Nikhlesh Jindal-10BSPHH010968 Ankit Grover-10BSPHH010099 Anuj Grover-10BSPHH010134 Nitika Thakur-10BSPHH010491 Nabarun Saha-10BSPHH010428

INDEX EXECUTIVE SUMMARY……………..……………………………………………………………………2 PROJECT AT A GLANCE……………………………………………………………………………….…3 SECTION – 1 INTRODUCTION TO THE PROJECT………………………….…………………………………………6 SECTION - 2 PROJECT DESCRIPTION………………………………………………………………...……………….10

SECTION - 3 DEMAND ANALYSIS AND JUSTIFICATION OF THE PROJECT…………………..………………12

SECTION - 4 TECHNICAL FEATURE & EQUIPMENTS OF THE PLANT…………………………………………15

SECTION-5 POWER PLANT CONFIGURATION AND SPECIFICATIONS OF MAIN PLANT EQUIPMENT……………………………………………………………………………………………...…17

SECTION - 6 OPERATION AND MAINTENANCE……………………………………………………………………..31

SECTION - 7 SWOT ANALYSIS…………………………………………………………………………………………..37

SECTION - 8 PLANT LAYOUT & PROJECT IMPLEMENTATION……………………………………...………….40 SECTION – 9 ESTIMATED PROJECT COST……………………………………………………………………………42 SECTION – 10 ESTIMATED POWER GENERATION COST…………………………………………………………...44

1|Page

(A)

EXECUTIVE SUMMARY The Electricity Act, 2003, paves way for an innovative approach to solve our country’s power problems. It has paved the way for a competitive environment; open access to existing transmission and distribution network to transmit electricity across regions; de-licensing of generation, captive power and dedicative transmission lines; licensing of distribution and supply companies and the restructuring of State Electricity Boards

The Ministry of Power have a mandate to promote cogeneration and renewable sources for Power generation under Nodal agencies and hence it will play a major role in mainstreaming renewable energy sector.

The advantage or renewable

resources includes their capacity to produce energy without producing carbonbased warming and polluting agents into the atmosphere. The financial cost of its applications is not always cheap but if the environmental costs of using fossil are accounted for, renewable energy wins hands-down. There are also indirect savings on health and its costs as there are no harmful emissions.

In the above backdrop, Sahil Energy Pvt. Ltd., has decided to set up a 5MW Solar Power Plant. This Detailed Project Report (DPR) brings out all technical details and overall costs justifying the selection of the project. The total power generation is envisaged to be 5MW from Solar Photovoltaic Cell. It is a very important document that is required for Environmental Impact Assessment (EIA) studies, fixation of tariff, finalizing Power Purchase Agreement (PPA) and also for submission to Financial Institutions for obtaining project funding. The total project cost is expected to be Rs85 Crores and the average cost of generation is expected to be Rs.12.86 /kWh.

2|Page

(B)

PROJECT AT A GLANCE

1.0

GENERAL

1.1

The Project

5MW Solar PV Grid Connected Power Project

1.2

Owner

SAHIL ENERGY

1.3

Location of Plant

ANANTAPUR DIST.

1.4

Location

Kadiri

1.5

Distance from District Headquarter

1.6

Access by Road

Chennai Mumbai National highway

1.7

Access by Rail

Kadiri Railway station

1.8

Access by Air

Satya Sai Airport Anantpura

1.9

Telecommunications

Telecommunication facility available

1.10

Land

It is proposed to install 5MW on the land, admeasuring about ………… Acre, which is already demarcated

1.11

Land Characteristics

Barren Land Non Agricultural Land

1.12

The Geographical location of the project site

13'-40' and 15'-15' Northern Latitude and 76'-50' and 78'-30' Eastern Longitude

1.13

Irradiation details considered

Kadiri, Anantpur(Dist.)

1.14

Type of Module Mounting Structure

Fixed Structures, Earth Mounted

1.15

Type of PV Modules Considered for Crystalline the offer

1.16

Proposed Capacity

5 MWp

1.17

Capacity of each PV Module

200 Wp

1.18

Invertors Capacity

100 KVA x 50 Nos.

1.19

Projected Energy Production per year

8.3 MU(Assured)

3|Page

1.20

Total Project Cost

4|Page

Rs 80. CR

SECTION - 1 INTRODUCTION TO THE PROJECT

5|Page

INTRODUCTION World Economic growth is driven by energy, whether in the form of finite resources such as coal, oil and gas or in renewable forms such as hydroelectric, wind, solar and biomass or its converted form.

This energy generation and consumption

strengthens the nation’s industries, vehicles, homes and offices.

It also has

significant impact on the quality of the country’s air, water, land and forest resources. For future growth to be both rapid and sustainable, it needs to be as resource efficient and environmentally benign as possible. GENERATION OF ELECTRICITY & IMPORTANCE OF RENEWABLE ENERGY The growth in installed power generating capacity has not kept pace with the projected demand. To solve this problem, it is necessary to set up more power plants and most of these power plants will be either fossil fuel based or hydro electric units. However, the conventional power stations cause enormous damage to be environment due to pollution and other side effects. Renewable energy sources energy source are wonderful options because they are limitless. These will not be exhausted though fossil fuel will be gradually exhausted in course of time. Also another great benefit from using renewable energy is that most of these sources do not pollute the environment; the way burning of fossil fuels dose. SOURCE OF GREENHOUSE GAS The greenhouse gas emissions (GHG) come primarily from the combustion of fossil fuels in energy use. Energy use is largely driven by economic growth with shortterm fluctuations in its growth rate created by weather patterns affecting heating and cooling needs, as well as changes in the fuel used in electricity generation. The burning of fossil fuels produces around 21.3 billion tones of Carbon Dioxide per year, but it is estimated that natural processes can only absorb about half of that amount, so there is a net increase of 10.65 billion tones of atmospheric carbon dioxide per year. Carbon dioxide is one of the GHG that enhances radioactive forcing and contributes to global warming, causing the average surface temperature of the earth to rise. Environment scientists predict that this will cause major adverse effects, including reduced biodiversity.

6|Page

The electricity sector is unique among industrial sectors in its very large contribution to emissions associated with nearly all air issues. Electricity generation produces a large share of nitrogen oxides and sulphur dioxide emissions, which contribute to smog and acid rain and the formation of fine particulate matter in addition to carbon dioxide. In addition, this sector has significant impacts on water and habitat and species. In particular, hydro dams and transmission lines have significant effects on water and biodiversity WORLD ENERGY SCENARIO It was estimated that in 2005, 86% of primary energy production in the world came from burning fossil fuels, with the remaining non-fossil sources being hydroelectric 6.3%, nuclear 6.0%, and renewable energy sources, i.e. geothermal, solar, wind, biomass and wastes contributed only 0.9%. BACKGROUND OF THE PROJECT Large multi-megawatt PV plants, approximately to 50 MW, are now in operation in the world. Solar Photovoltaic (PV) is known to be an important energy source for developing countries like India. Its importance is now being reaffirmed even by developed countries in view of its renewable and environment friendly character.

In our

country also, optimum utilization of solar energy could not only lead to savings in conventional energy but also result in many indirect benefits. In India 2MW solar PV now are commercially operated by independent power producer. But till now solar technology is expensive compared to other technology and significant financial assistance from government is needed to the developers and operators of new plants. In view of this, the Ministry of New & Renewable Energy Sources has been promoting electricity generation from Solar PV in Mega-Watt level. These projects are covered under the Grid Interactive Solar PV Power Generation Projects of Ministry of New & Renewable Energy Sources, Govt. of India. The Ministry initiated the programme to establish as a viable and environment friendly electricity generation option.

7|Page

BARRIERS IN DEVELOPMENT OF THE PROJECT

The project has been identified with some barriers as mentioned below: (a)

Higher capital cost – The initial capital investment of the project is so high compared to other conventional power Project, so per MW cost is high.

(b)

Low Capacity Utilization factor – the total unit generation is low compared to other electricity generation system, because maximum of 6 hours in a day plant gets the solar light and generates the power.

The project being first of its kind in the state, thee could be more risks and barriers which might surface as the project progresses and it is difficult to enumerate all at this stage. BENEFITS OF GRID CONNECTED SOLAR PV POWER PLANT (a)

Power from the sun is clean, silent, limitless and free

(b)

Photovoltaic process releases no CO2, SO2 or NO2 gases which are normally associated with burning finite fossil fuel reserves and don’t contribute to global warming.

(c)

Photovoltaics are now a proven technology which is inherently safe as opposed to other fossil fuel based electricity generating technologies.

(d)

No fuel is required for generation, so fuel cost of power generation is zero.

(e)

Solar power shall augment the needs of peak power needs

(f)

Increase the grid reliability i.e., voltage and frequency

(g)

Solar Powered Grid Connect Plants can act as tail end energizers, which in turn reduces the transmission and distribution losses.

(h)

Provides a potential revenue source in a diverse energy portfolio

(i)

Assists in meeting renewable portfolio standards goals

(j)

Generation of electricity from Solar PV is totally free of Green House Gas emission.

8|Page

SECTION - 2 PROJECT DESCRIPTION

9|Page

INTRODUCTION The proposed 5MWp solar power plant project will generate electricity from non-conventional sources. The project will use “polycrystalline” technology for the first time in the state for producing power by solar energy.

This

project envisages generation of safe, reliable electricity in an environmentally friendly way. BRIEF DETAILS OF PROJECT AREA Kadiri

is a taluka under Anantpura District situate in

Proposed Solar Power Plant is situated in Kadari

Land area of power plant

10 | P a g e

:

20Acres

Andhrapradesh

SECTION - 3 DEMAND ANALYSIS AND JUSTIFICATION OF THE PROJECT

11 | P a g e

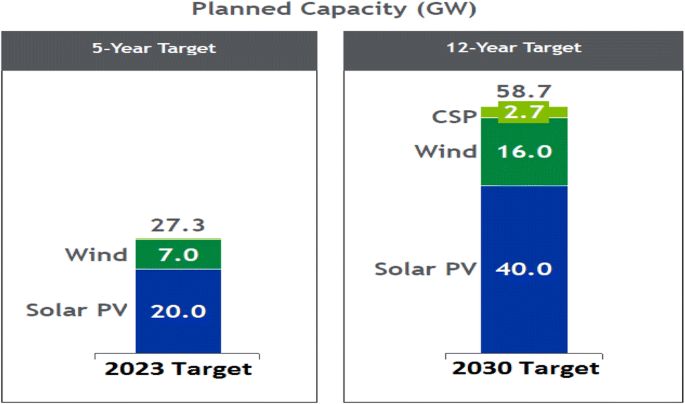

INTRODUCTION It is well know fact that electricity is the most essential input for growth and development of any state. Andhra pradesh is planning to go rapidly in both the industrial and agricultural sectors and consequently the demand for power is on the rise. However, despite Andhrapradesh possessing immense potential of power ranging from Coal to natural gas not taken place on a scale commensurate with the possibilities. As a result there exists a big gap between conventional and Nonconventional power generation for power in the State. SOLAR POWER POTENTIAL IN INDIA India is endowed with rich solar energy resource. The average intensity of solar radiation received in India is 200 MW/km square (megawatt per kilometer square), but the amount of solar energy produced in India is merely 0.5% compared to other energy resources till date India just have 2.12 megawatts of grid-connect solar generation capacity. As part of the National Solar Mission, the ministry aims to booster the annual photovoltaic production to at least 1,000 megawatts a year by 2017. With an installed capacity of 123 GW, the country currently faces energy shortage of 8 percent and a peak demand shortage of 11.6 percent, In order to sustain a growth rate of 8 percent, it is estimated that the power generation capacity in India would have to increase to 306 GW in the next ten years which is 2.5 times current levels.

12 | P a g e

13 | P a g e

SECTION - 4 TECHNICAL FEATURE & EQUIPMENTS OF THE PLANT

14 | P a g e

BASIC SYSTEM DESCRIPTION Solar Photovoltaic power generator consists of solar modules in series and parallel connections, these convert solar radiations into DC electrical power at the pre-determined range of Voltages whenever sufficient solar radiation is available. The individual crystalline solar cells are connected together in a module (in series connection), which are hermetically sealed to survive in rugged weather conditions and ensures optimum performance during its ling life In order to achieve a higher system voltage, modules are installed in a row arrangement, called a string. A higher system voltage has the advantage of lesser installation work, higher efficiency of the entire plant and usage of smaller cross section cables. Calculated no. of strings is connected in parallel by cables in Junction Boxes. These junction boxes not only act as a junction point but also monitor each string output which will be fed to the central monitoring and analysis system. Outputs from many such junction boxes are connected in parallel in the Main Combiner Box (MCB). This Main Combiner Box output is fed to the central inverters/Power Control Unit (PCU) to invert solar generated DC power in to conventional 3 phase AC power. Central inverter or PCU operate on MPPT (Maximum power point tracking) mode to ensure maximum output from the solar generators at different ambient conditions. Central inverters use higher system voltages to reach very high plant efficiency. Furthermore, installations can be expanded with additions of more modules without problems. AC power from inverters will be fed to LV panel which in turn will be stepped up through transformer. Power at 11kv/22Kv will be transmitted by overhead transmission line to grid.

15 | P a g e

SECTION-5 POWER PLANT CONFIGURATION AND SPECIFICATIONS OF MAIN PLANT EQUIPMENT

16 | P a g e

The capacity of the Proposed Solar Power Plant has been fixed at 1 MWp.x 5Nos. The principle factors considered for designing and selection of proposed plant are local solar radiations, ambient conditions and electrical load characteristics of major system namely the array and power conditioning unit. Moreover, the proposed plant is situated at remote village location, so maximum use of local materials available on site for construction and to retain or preserve the original appearance of the sire and the environment are considered SR.NO. ITEM PV arrays 1.0 Modules in a string 2.0

50 Nos 18 Nos

3.0

String in a array

28Nos

4.0

Inverters

50 X 100 KVA

5.0

Transformer

5Nos

SPECIFICATION OF MAIN PLANT (A)

SOLAR PV MODULE

SR.NO.

ITEM

1.0

Output Power-Pmax (Watt)

200 Wp

2.0

Voltage at maximum power-Vmp (Volts)

28.60 V

3.0

Current at maximum power-Imp (Amps)

7.02

4.0

Open circuit voltage – Voc (Volts)

36

5.0

Short circuit current-Ise (Amps)

7.55

6.0

Type of solar PV cell

Poly Crystalline

7.0

Dimensions

1619MM x 1002MM

8.0

weight

23.50Kg

17 | P a g e

(B)

SOLAR INVERTER

SR. NO. 1.0

ITEM Nominal Voltage

230/400 volts three phase, 4 Wire,

grid

tracking

Nominal

voltage can be adjusted by ± 10% via system stepoints.

2.0

Output Frequency

50Hz ± 0.5% inverter to follow grid frequency up to ±3Hz of the nominal output frequency during normal operation

3.0

Continuous rating

100 kw at unity power factor

4.0

Max DC link Voltage Range

800 volts DC

5.0

MPPT Range

397 to 585 Volts DC

6.0

Control Type

Voltage source, microprocessor assisted output regulation

7.0

Waveform

PWM for low THD, sine wave output

8.0

THD

Less than 3 %

9.0

Efficiency

Up to 94%

10.0

Internal protection system (using electronic detection)

Internal

continuous

overload

protection inverter peak current (short circuit) protection Heatsink over

temperature

over/under

18 | P a g e

grid

protection voltage

AC

voltage protection over/under grid frequency protection Anti islanding protection

11.0

Alarm Signals

Via system fault relay (voltage free contact)

12.0

Front panel display (LCD)

LCD

panel

with

membrane

keypad displaying the following inverter

per

phase

voltage,

current, kW, kVA and frequency Grid

voltage

and

frequency

inverter (grid ) on line status PV panel voltage Solar charge current and

ambient

temperature

individual power stage heat sink and cabinet temperature solar radiation (optional ) Inverter Import & export kWh summation solar kWh summation system stepoints and event logs

13.0

Front Panel Controls (via keypad)

Auto

mode

connect selection

selection-

Inverter System

Grid

Test

Mode

off

Mode

selection Fault Reset

14.0

Front Panel Indicators

Inverter On line control power supply OK system Fault

15.0

Circuit Breakers

ACB / MCCB

16.0

RFI

Design conducted emissions

19 | P a g e

to

minimize and

radiated

both RFI

17.0

Earthing Provisions

AC bypassing to earth on inverter and DC inputs

18.0

Operating Temperature Range

5-50 degrees Celsius

19.0

Humidity

0-90% non condensing

20.0

Enclosure

Rate for IP30

21.0

Computer port

Isolated RS232 port. Provision for Mod bus protocol. WiFi, LAN protocol

22.0

Computer Access

The system includes a local access

port

as

well

as

a

telecommunication dialup facility incorporating either a standard PTSN modem or GSM modem for remote access. SCADA package will be windows based OPSComs.

23.0

System feature

Adjustable logging repetition from 1 sec to 900 seconds Storage capacity of up to 3 year with 10 min logs Time and date stamped log

entries

Time

and

Date

annotated fault log, holding the fault description and operating statistics View and change system stapoint configurations remotely Bulk

log

download

for

data

importation into a spreadsheet where applicable.

20 | P a g e

24.0

Logging Attributes

A summary of the data logging abilities supply with the

control

system for instantaneous viewing and periodic logging are listed below:

System

summations

inverter

import and export kWh Solar (C)

415V PCC x 125 Nos

SR. NO.

ITEM

Parameters Inverter volts, amps, kW, kVA, frequency Grid volts and frequency

1.0

TECHNICAL PARAMETERS

1.1

System particulars

1.1.1

Rated voltage and phases

1.1.2

Frequency

1.1.3

System earthing

21 | P a g e

Solar

panel

temp.

Ambient temperature PV panel voltage Solar charge current Heat sink & cabinet temperatures solar 415 V, 3 Phase, 4 wire radiation (with external 50 Hz pyranometer optional). Effectively earthed

1.1.4

Maximum system voltage

1.1.5

One minute power frequency withstand

457 V

voltage

2.5 kV

(a) Power circuit

1.5 kV

(b) Control circuit 1.1.6

Continuous current rating of busbars (a) PCC

1.1.7

2000A

Short circuit withstand (a) PCC

50 kA/1 sec.

1.1.8

Reference ambient

500C max.

1.1.9

Max temp of busbars at rated current

900C

2.0

CONSTRUCTIONAL REQUIREMENTS

2.1

Sheet steel thickness

2.1.1

Frames

2.5 mm cold rolled

2.1.2

Doors

2.5 mm cold rolled

2.1.3

Covers

2.0 mm cold rolled

2.2

Degree of protection

IP 52

2.3

Colour finish shade as per IS: 5

Seven tank process painting with epoxy based

2.3.1

Interior

Glossy white

2.3.2

Exterior

Shade 631

2.4

Busbar material

All alloy of E 91 E grade. For main bus bars - copper for Auxiliary bus bars fully insulated

2.4.1

Bus bra installation

2.5

Earthin bus.

22 | P a g e

Fully insulated

2.5.1

Material

2.5.2

Size

GS

(a) for PCC

By bidder

2.6

Clearances in air of live parts

5-50 degrees Celsuis

2.6.1

Phase to Phase

25.4 mm

2.6.2

Phase to earth

19.4 mm

2.7

Single front design

All panels

2.8

Draw out / Fixed type design

Rate for IP30

2.8.1

PCC-ACB

Draw out type

2.8.2

MCCB

Fixed / plug in type

2.9

Incoming supply to PCCs

Through cables

2.10

Vertical cable alley

Minimum 250 mm

2.11

Cable entry

Bottom

3.0

INCOMER CIRCUIT BREAKER FOR PCC

3.1

Circuit breaker type

Fully draw out type Air circuit breaker

3.2

No. of Phases

4 pole

3.3

Rated breaking capacity

50 kA

3.4

Short circuit withstand current

50 kA for 1 Second

3.5

Rated current

Refer enclosed SLD

3.6

Type of operating mechanism

Motorized spring charged Motor voltage, 220 V Ac, 1Ph.

3.7

Shunt trip require Yes/No

Yes

3.8

Relays / releases / control

Overload / Earth fault / short circuit / static with settable settings (Microprocessor based)

3.9

Remote communication

Through serial link, Port Rs. 485 with formation of bus wires and communication modem

3.10

Breaker Test-Service selector switch

Required

3.11

Local- Remote selector switch

Required

3.12

Minimum no. of auxiliary contacts

4 No, 4 NC spare for purchaser’s use

4.0

OUTGOING CIRCUIT BREAKER FOR PCC

4.1

Circuit breaker type

23 | P a g e

MCCB

4.2

No. of phases

TP with N

4.3

Rated breaking capacity

50 kA for 1 sec.

4.4

Type of operating mechanism

Manual

4.5

Shunt trip required

Yes

4.6

Relays / series releases

Overload / short circuit

(D)

TRANSFORMER

SR.

ITEM

NO. 1.0

GENERAL

1.1

Application

Power Transformer

1.2

Quantity

1 No.

1.3

Installation (Indoor / Outdoor )

Outdoor

1.4

Type (Auto / 2 Winding / 3 Winding)

2 Winding

1.5

Rating

1.6 MVA

1.6

Cooling

ONAN

2.0

TEMRATURE RISE

2.1

Ambient temp. maximum

45 C

2.2

Temp. Rise of oil by thermometer

50 C

2.3

Temp. Rise of winding by resistance method

55 C

2.4

Impedance at rated current frequency at 75 C

6.25%

24 | P a g e

3.0

TAPPING: Off Load Tap Changer

3.1

Tapping on winding (HV)

+5 to -5%

3.2

Total tapping range

+10

3.3

Step

2.5% ( 5 taps)

4.0

RATING

4.1

No load voltages

4.2

Frequency

5.0

TERMINAL CONNECTION

5.1

HV Winding Line end

(a) HV Winding

11 kV

(b) LV Winding

433 V

50 Hz

433 V

XLPE cable (with heat shrink terminations)

5.2

HV Winding neutral end

----------

5.3

LV Winding Line / N end

XLPE cable (with heat shrink terminations)

5.4

LV Winding neutral bushing

5.5

Earthing conductor for Transformer body

6.0

SYSTEM DATA

6.1

System voltages

(a) HV Nominal / Highest 11/12 kV (b) LV Nominal / Highest 0.433/0.457 kV

6.2

Fault levels

(a) HV (6.6kV) system 40 kA (b) LV (415V) system 50 kA

6.3

System Neutral Earthing

(a) HV (11kV) Earth through Resistor (b) LV (415V) Solidly Earth System

7.0

WINDING

7.1

Material of Winding

Copper

7.2

Winding connection & vector group

HV (11kV) Delta LV (433V) Star

7.3

Transformer neutral Type of Earthing

8.0

MISCELLANEOUS

8.1

Wheels

Separate Neutral bushing for earth connection (suitable for 1.1kV grade) (a) Material -- G.I. strip (b) Size -- 60 x 12 mm

Dyn 11

(a) HV – Not applicable (b) LV – Solidly Earthed (a) Plain / Flanged : Flanged (b) Unidirectional / Bidirectional : Bidirectional

25 | P a g e

8.2

Winding temp. indicator required

Yes

8.3

Any special final paint required (Epoxy etc.)

Epoxy painting

9.0

Additional

features

for

terminal

connection 9.1

HV cable box:

With disconnecting chamber, phase segregated type, provided with space heater thermostat

9.2

LT cable box

9.3

Separate LV Neutral bushing:

9.4

Neutral CT after bifurcation

Required for earth connection to earth pit 2000/1 A, class PS for 64R, 2000/1 A, CL 5P10, 15 VA for 51NS shall be provided

NOTES: (1) Transformers shall be provided with necessary accessories

(E)

HT CABLES

SR. NO.

ITEM

1.0

Voltage Grade

11 kV (UE) grade cables, heavy duty

2.0

Conductor

Stranded Aluminium

3.0

Conductor Screen

Semi – conducting compound

4.0

Insulation

XLPE

5.0

Inner sheath

Extruded PVC (Type ST-2)

6.0

Outer sheath

Extruded PVC (Type ST-2)

7.0

Armoring

8.0

Cable Operating Temperature

Galvanized steel strips for multi-core cables and non-magnetic Aluminium wires for single core cables 90 C

9.0

Short

circuit

withstand

current 40kA for 1 sec.

capacity 10.0

Short circuit withstand temperature

(F)

LT CABLES

SR. NO.

ITEM

1.0

POWER CABLE

1.1

Voltage Grade

26 | P a g e

250 C

UNIT

V/V

1100V for 415V system

1.2

Frequency

Hz

50

1.3

Earthing system

-

1.4

Conductor

-

1.4.1

Material

-

1.4.2

Max withstand Temp

-

(a) Normal condition

C

90

(b) Short circuit condition

C

250

1.4.3

Conductor type

-

Stranded

1.4.4

Grade

-

H4

1.5

Insulation

-

1.5.1

Material

-

XLPE

1.5.2

Reference standard

-

IS 7098, Part I and Part II

1.6

Inner Sheath

-

1.6.1

Material

-

FRLS PVC

1.6.2

Type

-

ST2

1.7

Outer Sheath

-

1.7.1

Material

-

FRLS PVC

1.7.2

Type

-

ST2

(G)

EARTHING & LIGHITNG PROTECTION

Solidly earthed system for 415V system

Annealed Cu

CODES & STANDARDS The earthing of all outdoor equipment and provision of associated earthing systems, electrodes and connections shall be in accordance with the recommendations in the latest IEEE 80/IS 3043. DESIGN CRITERIA GROUNDING SYSTEM The grounding design calculation shall conform to ANSI / IEEE Standard 802000. Earth electrodes shall be provided throughout the plant areas along with the main earth grid. The number of earth electrodes shall be according to achieve the total earth grid resistance less than one (1) ohm. Earth electrodes shall be provided in earth pits. The earth pits shall be of two types namely treated with

27 | P a g e

test links and untreated. Earth electrodes shall be of heavy duty GI pipes, 40 mm dia and 3 meter long. The main buried grid conductors shall be connected to all the earth electrodes to form a total earth grid.

28 | P a g e

GROUNDING MATERIAL Galvanised steel flats of required size shall be used as per approved design. In any case the minimum size shall be 75 x 10 mm. GS strip for earthing conductor. Treated earth pits shall conform to relevant INDIAN Standards. The earth grid shall be installed specified / approved depth of minimum 600mm. EQUIPMENT EARTHING The frames of all electrical equipment and structural steel work shall be earthed by connection to earth grid by branches of same cross sectional area of the earth grid. LIGHTINING PROTECTION SYSTEM Power plant needs protection against Lighting. The system will be designed as per IS: 2309 and Indian Electricity Rules. Vertical air termination of 40mm diameter, 3 M long shall be provided above highest point of array to provide radius of protection full array. (H)

STRUCTURAL MOUNTING EQUIPMENT

SR. NO.

ITEM

1.0

Type

Ground Mounting

2.0

Material

MS Galvanized

3.0

Overall dimension

As per design

4.0

Coating

Hot dip (Galvanized) Minimum of 130 Micron size

5.0

Wind rating

150 km / hr

6.0

Tilt angle

30

7.0

Foundation

PCC

8.0

Fixing type

SS 304 Fastners

29 | P a g e

SECTION - 6 OPERATION AND MAINTENANCE

30 | P a g e

OPERATION AND MAINTENANCE PHILOSOPHY The proposed Organization structure for the operation and maintenance (O&M) of the power plant is presented in the exhibit.

In order to ensure a high level of

performance of the power plant, it is proposed to induct experienced O&M engineers from the very beginning of the project. BASIC STRUCTURE OF THE O&M TEAM The basic structure and the broad functional area within the O&M organization would be as follows: The Plant Manager would have the primary responsibility for the O&M of the power plant.

The organization will compromise of four broad functional areas viz.

Operation, Maintenance, Technical and Administration. The basic duties covered under each of these functional areas would be as follows: Operation (a)

Operation of main generating equipment, switch yard and other auxiliary plant.

(b)

Except for the Power Station Superintendent all other operating personnel would work one shift basis.

(c)

The day to day operation of the power plant will be controlled by the Manager who will be assisted by the Control room operators and engineers.

Maintenance (a)

Maintenance of mechanical and electrical plant, control systems, buildings, roads, drainages and sewage systems etc.

(b)

Operation of the plant, planning and scheduling maintenance works and deciding the requirement of spare parts

(c)

The Plant Manager will be assisted by departmental engineers, who take care of the maintenance aspects of all mechanical, electrical and I&C requirement

31 | P a g e

(d)

Trained technicians will be employed to assist the maintenance group in day to day maintenance of the plant.

Administration The main responsibilities of this department will be as follows: (a)

Purchase

(b)

Plant Security

(c)

Liaison with local labour officers

(d)

Stores management

(e)

Medical Services

(f)

Transport services

FACILITIES TO BE EXTENDED TO THE EMPLOYEES The number of employees required for operation of the proposed power plant will be around 10 numbers.

The personnel required for administration and finance &

accounts also will be provided. The following facilities will be provided in the power plant. (a)

Administration Building and Technical Office

(b)

Stores

(c)

Time and security offices

(d)

First Aid and Fire Fighting Station

(e)

Toilets and Changes rooms

32 | P a g e

Ordinary Maintenance Ordinary Maintenance, which covers routine checking and minor refurbishment activities to be performed according to operation manuals of components / equipments in operating conditions. Emergency Maintenance Emergency Maintenance, which is corrective maintenance to be performed when a significant failure occurs.

To minimize forced outages duration, an effective

Emergency Maintenance must be supported by: (a)

A proper stock of spare parts

(b)

Permanent monitoring and diagnostic systems for main components.

Maintenance Plan and Scheduled Maintenance Scheduled maintenance is carried our according to maintenance plan, which should be discussed and optimized according to the needs of the customer / client. The maintenance plan is based on scheduled outages for the following components: (a)

Cleaning of Solar Module

(b)

Power Processing System

(c)

Switchyard equipment

MAINTENANCE MANAGEMENT SYSTEM The maintenance of this plant will be carried out as per the above philosophy. This system aims at maximizing the availability of the plant, while ensuring minimum maintenance cost and safety of the plant and personnel. SPARE PARTS MANAGEMENT SYSTEM

33 | P a g e

The primary objective of spare part management system will be to ensure timely availability of proper spare parts for efficient maintenance of the plant without excessive build-up of non-moving and slow moving inventory. The spare parts management system for this project will cover the following areas: (a)

Proper codification of all spares and consumables

(b)

Spare parts indenting and procurement policy

(c)

Ordering of critical mandatory and recommended spares

(d)

Judicious fixation of inventory levels and ordering levels for spare parts based on experience.

(e)

Development of more than one source of manufacturer / supplier whenever practicable.

AVAILABILITY OF O & M MANUALS All contracts include provision of at least 6 sets of details O&M manuals, which will be distributed to all departments concerned well in advance from the commissioning date of the power plant to avoid problems in preparation of commissioning documents as well as proper installation and commissioning procedures of various equipments. SPECIAL TOOLS AND TACKLES All contracts will include the provision for supply of one set of all types of special tools and tackles, which are required for installation, commissioning and proper maintenance of plant and equipment.

34 | P a g e

CHECKLISTS AND PROTOCOL A detailed checklist for the various equipments, supplemented with the checklist submitted by the supplier shall be drawn and logged for future reference. This will also form part of the plant’s base history / datum. Whenever an equipment in commissioned, the important parameters of that particular equipment should be observed for a period of eight hours and the readings shall be logged as per the log sheets. These activities shall be performed in the presence of the customer / consultant and a protocol shall be signed. SAFETY AND PROTECTION The importance of safety and the protection of personnel and equipment cannot be overemphasized. The system must be designed to minimize hazards to operation and maintenance personnel, the public, and equipment. The control subsystem must be equipped with various fuses, built-in fault detection and protection algorithms to protect the users, the loads, and the PV system equipment. The safety of an operator or technician is of the utmost importance. Personnel must be protected from electric shock by following all available safety practices. Such as displaying high voltage warning signs wherever necessary. In general, the system must adhere to the IS Codes and standards dealing with safety issues. Some of the important safety criteria are as follows: (a)

Electrical components should be insulated and grounded

(b)

All high voltage terminations (> 50 Vdc) should be properly covered and insulated

(c)

All component with elevated temperatures should be insulated against contact with or exposure to personnel

(d)

Structures should be grounded and ground fault relays installed to give warning of ground faults in the array or other electrical components.

35 | P a g e

SECTION - 7 SWOT ANALYSIS

36 | P a g e

SWOT ANALYSIS. Non – Conventional Sources, which are renewable in nature, are termed as the alternate sources of energy. The Challenges of the present – energy scenario offer us a window of the opportunity in the form of renewable energy sources. The Power from the sun is clean , silent , limitless and free. Photovoltaic (PV) process releases no CO2 , SO2 or NO2 gases which are normally associated with burning finite fossil fuel reserve and don’t contribute to global warming . Solar power shall augment the need of peak power needs & increases the grid reliability I.e , Voltage and frequency. Solar Powered grid connect plants can act as tail end energizes , which in turn reduces the transmission and distribution losses. (a)

Geographically India is situated at northern hemisphere near the Equator. So India gets maximum solar irradiation and there is ample of scope to produce the power from solar PV. But till now this area is totally virgin area for producing power.

(b)

This is true that solar PV efficiency is very low compared to other power generation systems , Lots of R&D is going on the improve the efficiency. Solar PV generates electricity only at day time , So the proposed solar PV Power plant generates power on an average only about six hours in day time.

(C)

India is potentially one of the largest markets for solar energy in the world. The estimate4d potential of power generation through solar photovoltaic system is about 20 MW/Sq.km in India. It is useful for providing grid quality, reliable power in rural area where the line voltage is low and insufficient cater to connected load. Recent Government incentives and policies have been providing the momentum for PV in India . The Government of India already declared national Action plan on climate change released in mid 2008, identifies eight critical mission – one of which is the National Solar Mission.

(d)

In comparison to other sources of power generation, the PV solar power is totally dependent in nature . The capacity utilization factor of such type of plant is only 19%. Because averagely in the year we get 6 hr sunlight

37 | P a g e

in a day . Only this particular interval solar plant generates electricity. In comparison to other conventional power generating units, solar power generating unit has many advantages like.

(a)

No fuel is required for power generation.

(b)

Operation & Maintenance Manpower required is less.

( c)

Plant will be running smoothly for a long period as compared to other conventional power generation units.

(d)

In environmental perspective , solar power plant generates clean energy and gets maximum clean development mechanism (CDM) benefit as compared to other conventional power generation units.

Considering all the above points, solar power generating potential is always ahead of all other conventional power generating units in economical & Environment point of view.

38 | P a g e

SECTION - 8 PLANT LAYOUT & PROJECT IMPLEMENTATION

39 | P a g e

INTRODUCTION.

This layout of the plant and facilities for the proposed solar power plant is largely dictated by its location, shape and road etc. Involving minimum eviction, the wind rose pattern, land use pattern of adjoining area and the direction of power evacuation.

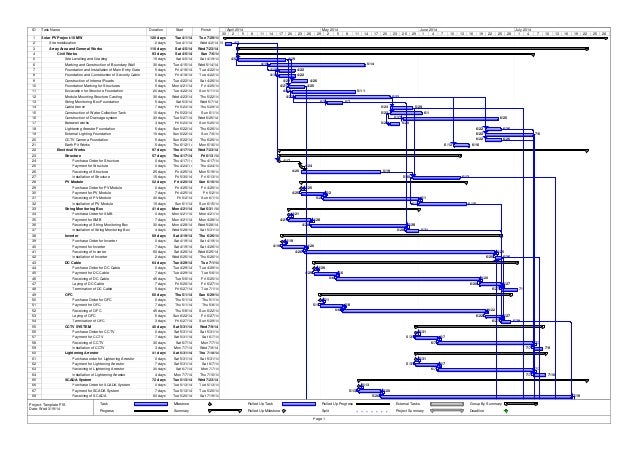

IMPLEMENT CONCEPT The project is planned to be implemented at the earliest . The most essential aspect regarding the implementation of this project is to ensure that the project is completed with in the schedule , spanning 6 months from the placement of purchase order. A good planning , scheduling , and monitoring program is imperative to complete the project on time and without cost overruns.

The project zero date start once the kick- off meeting has taken place and the advance payment has been received.

PROJECT IMPLEMETATION STRATEGY.

It is envisaged that the project will have the below mentioned phase of activities . These phases are not mutually exclusive ; to implement the project on fast track basis some degree of overlapping is envisaged.

40 | P a g e

Phase I

Project Development

Phase II

Finalization of the Equipment and contracts

Phase III

Procurement and Construction.

Phase IV

Plant Commissioning

SECTION – 9 ESTIMATED PROJECT COST

41 | P a g e

BASIS FOR COST ESTIMATION The capital cost of the plant has been estimated taking into account the cost of civil & structure works, transportation, installation, testing, commissioning charges and contingencies. Land cost is not considered as land is already available. The cost of material and electrical equipment has been estimated based on budgetary quotation received previous quotations for other projects and in house cost data suitable altered. Excise duty is exempted as per MNRE consideration. Packing, forwarding , inland transportation and insurance at the rate of 2.5% for all equipment and systems including spares have been considered. Erection, testing and commissioning charges are considered as 8% of supply cost for mechanical and electrical equipment. 3% of the equipment cost has been considered towards cost of initial spares. Cost of civil works has been estimated based on data available for similar projects. Power plant life is considered as 25 years.

42 | P a g e

SECTION – 10 ESTIMATED POWER GENERATION COST

43 | P a g e

COST OF POWER GENERATION Basis for Generation Cost Estimation Debt-Equity Ratio shall be 70:30 Rate of interest on loan shall be 10.0% p.a. Depreciation shall be 10.34% for plant & machinery and 3.34% for Civil work The working capital is insurance expenses for one year in advance and one month requirement of spares and consumables Eligibility for working capital loan is 75% of total working capital & interest rate on the loan is 12% p.a.

44 | P a g e

Refrences: http://www.businesswire.com/news/home/20110927005580/en/Satcon-Chosen-Landmark-5Megawatt-Project-Arizona http://www.google.co.in/search?sourceid=chrome&ie=UTF-8&q=Project+of+5+Mega+Watt http://www.bloomberg.com/news/2012-01-04/world-bank-backed-azure-completes-5megawatt-solar-power-project.html http://www.reeep.org/485.17860/greenergy-renewables-pvt-ltd.htm http://www.airvoicegroup.in/gepl.htm http://gpenergy.net/ http://www.outbacksolarproject.com/2011/10/outback-5-megawatt-solar-project.html http://green.tmcnet.com/channels/solar-power/articles/223414-satcon-chosen-landmark-5megawatt-project-arizona-western.htm http://www.renewablewire.com/solar-power/satcon-chosen-for-5-megawatt-solar-project-byarizona-western-college.html

Text Book: Project Finance In Theory And Practice- Stefano Gatti Project Appraisal and Finance – Prasanna Chandra

45 | P a g e

INTRODUCTION

Electricity generation is the leading cause of industrial air pollution in the country. Most of our electricity comes from coal, nuclear, and other non-renewable power plants. Producing energy from these resources takes a severe toll on our environment, polluting our air, land. Renewable energy sources can be used to produce electricity with fewer environmental impacts. It is possible to make electricity from renewable energy sources without producing CO2.

Renewable energy is energy derived from natural resources that replenish themselves over a period of time without depleting the Earth’s resources. These resources also have the benefit of being abundant, available in some capacity nearly everywhere, and they cause little, if any, environmental damage. Energy from the sun, wind, and thermal energy stored in the Earth’s crust are examples. For comparison, fossil fuels such as oil, coal, and natural gas are not renewable, since their quantity is finite once we have extracted them they will cease to be available for use as an economically-viable energy source. While they are produced through natural processes, these processes are too slow to replenish these fuels as quickly as humans use them, so these sources will run out sooner or later.

So this project is intended at the development of a solar based compressor free mini fridge. This fridge will be suitable for cooling purposes meant for small objects and will have a relatively small chilling time as compared to the normal refrigeration systems. Also for the backup, this fridge will be attached to a dynamo based charging system which will maintain the smooth operation of fridge in case of non-availability of solar power.

CONSTRUCTION AND DESIGN

Dimensions of the fridge

1. Outer Dimensions

Length: 30 cm

Breadth: 20 cm

Height: 21 cm (including the stands)

2. Inner Dimensions

Length: 25.5 cm

Breadth: 15.5 cm

Height: 8 cm

3. Volume of the fridge 3.162 Litres

Steps in the construction of the fridge

- Firstly a box of thermocol is made of given dimensions and then the inner walls of the box are covered with the aluminium sheet and the outer walls by the chart paper.

- The taping of the box from outer side is done so as to provide mechanical support and blocking of air.

- The two Peltier units are well placed in the two holes made in the box and kept on the heat sink with hot side attached to the heat sink surface and cold side inside the box.

- The heat sink is linked with a fan which is used to dissipate the heat of heat sink into the outer atmosphere i.e. out of the thermocol box. So, the hot side of peltier unit is unable to affect the temperature inside the box.

- All the electrical connections are made putting a switch for on/off and a LED as an indicator whether the fridge is working or not. Two batteries each of 12 Volts DC, 7.5 Ah are connected in parallel with the peltier units connected in series and the two cooling fans.

- All the electrical connections are made strong by soldering them and all the wires are arranged properly so as to avoid any inconvenience for the user.

WORKING OF THE PROJECT

Fridge

Solar Power Plant Project Report

- The fridge is provided power supply form a 12 volt DC 7.5 amphrs battery.

- To start the fridge, the switch on the fridge is turned on.

- When the switch is turned on, a led starts glowing indicating that the fridge is now online.

- Now two Peltier thermoelectric devices which are insulated from the cooling side and arranges in the fridge generates cooling effect on inner side and heat is dissipated on outer side.

- On the heat side of the peltier unit, a heat sink along with the fan works to dissipate the heat from the peltier unit in the outer environment.

- The Peltier thermoelectric Device will be so arranged in a box with proper insulation system and heat sink so that efficient cooling takes place at all the time.

- To turn off the fried, switch can be turned off. Then the glowing led will also stop glowing indicating no power for the fridge.

Battery charging

The batteries used in the fridge are charged from the solar panels using a charge controller rated 12volts, 10 amps. The battery is connected to the charge controllers which get supply from the solar panels and feeds it to the battery.